The Gekko Anti Slip Layers offer a revolutionary solution for improving safety and efficiency in material handling operations. Specifically designed for forklift forks, these magnetic anti-slip layers provide numerous benefits.

One key advantage of the Gekko Anti Slip Layers is their ability to reduce vibrations and noise during material handling tasks. By effectively absorbing shocks and vibrations, these layers minimize the impact on both the forklift operator and the surrounding environment. This not only enhances operator comfort but also helps prevent fatigue-related accidents.

Additionally, the Gekko Anti Slip Layers are incredibly easy to mount onto forklift forks. Their magnetic properties allow for quick installation without the need for any additional tools or equipment. This saves valuable time and effort, ensuring that operations can resume promptly.

Furthermore, these anti-slip layers offer exceptional grip and traction, even in challenging conditions such as wet or oily surfaces. This significantly improves load stability and prevents goods from shifting during transport, ultimately enhancing overall safety.

In conclusion, the Gekko Anti Slip Layers provide a reliable solution to enhance safety and productivity in material handling applications. With their ability to reduce vibrations and noise while offering easy installation and superior grip, they are an invaluable asset for any forklift operator or warehouse manager seeking to optimize their operations.

Ensuring the safety of orderpickers is crucial for both the well-being of workers and the productivity of operations. Orderpickers, also known as cherry pickers or stock pickers, are elevated platforms used in warehouses and distribution centers to retrieve items from high shelves.

The safety of orderpickers revolves around several key factors. First and foremost, it is essential to adhere to all safety guidelines and regulations set forth by relevant authorities. This includes proper training for operators, regular equipment inspections, and maintenance.

One critical aspect of orderpicker safety is understanding its rated capacity. Each orderpicker has a maximum weight limit that it can safely carry. Exceeding this limit can lead to instability and potential accidents. Operators must be knowledgeable about the rated capacity of their specific equipment and ensure that they do not overload it.

Furthermore, implementing safety features such as guardrails, non-slip surfaces on platforms, and emergency stop buttons can significantly reduce the risk of accidents while operating an orderpicker.

Regularly conducting risk assessments and identifying potential hazards within the work environment is also essential. This allows for proactive measures to be taken in order to prevent accidents before they occur.

By prioritizing safety measures for orderpickers, businesses can create a secure working environment that promotes productivity while minimizing the risk of injuries or damage to goods.

When it comes to forklift safety, one crucial component to consider is the condition of the forklift forks. Over time, these forks can experience wear and tear, particularly at the heel where they make contact with the ground. If the wear exceeds 10%, it is recommended to replace the forklift forks to ensure optimal safety.

Replacing worn forklift forks is essential for several reasons. Firstly, worn forks can compromise load stability and increase the risk of accidents or product damage. Secondly, worn forks may not properly engage with pallets or other materials, leading to instability during lifting and transporting operations.

By replacing forklift forks that have more than 10% wear at the heel, companies can prioritize safety in their material handling operations. It is important to regularly inspect and maintain all components of a forklift, including its forks, to prevent accidents and ensure smooth operations in warehouses or industrial settings.

When it comes to ensuring safety during lifting and moving operations, GenieGrips® are the ideal solution. These innovative products are designed to prevent punctures, tearing, or damage to merchandise, providing a reliable grip that enhances safety in various industries.

Whether you're working in a warehouse, distribution center, or any other environment where lifting and moving heavy objects is part of the job, GenieGrips® offer a practical and effective way to protect your merchandise. By securely gripping onto items such as boxes, crates, or pallets, these grips reduce the risk of accidents caused by slipping or shifting loads.

Not only do GenieGrips® enhance safety for workers by providing a secure grip on merchandise, but they also help prevent costly damages. With these grips in place, you can significantly reduce the likelihood of punctures or tears leading to product loss or spoilage.

In addition to their protective qualities, GenieGrips® are easy to install and remove. They can be quickly applied onto lifting equipment such as forklift forks or pallet jacks without complex tools or equipment. This makes them convenient for businesses looking to enhance safety without disrupting workflow efficiency.

In conclusion, when it comes to preventing punctures, tearing, or damage during lifting and moving operations, GenieGrips® provide an essential layer of protection. By investing in these innovative products, businesses can prioritize safety while minimizing the risks associated with handling valuable merchandise.

Currently, I am unaware of OSHA rules about the Magnaflux inspection of forklift forks. Since there are other areas in the world that this procedure is required on a 6 month or annual basis keep in mind industry-standard can creep into compliance standards. once we coat the forks with polyurethane, this type of non-destructive test would be next to impossible.

Thought this Interpretation might answer questions for some users.

Interpretation: 1-78

Subject: ANSI/ITSDF B56.1-2005, Section 4.2.3, Modifications, Nameplates, Markings, and Capacity and Section 7.5.9, Nameplates and Markings

Date Issued: March 13, 2006

Question (1): Section 4.2.3 states that “If a truck is equipped with front end attachments…”, does this include an attachment that is provided with the fork truck by the manufacturer?

Answer (1): Yes.

Question (2): Would this attachment be an attachment other than the standard equipped tines?

Answer (2): Yes. Forks are not considered to be an attachment.

Question (3): If an off the shelf attachment is purchased to use on the standard tines and the forklift manufacturer says that the attachment purchased will not affect the capacity or the safe operation of the truck, does the fork truck require a second nameplate?

Answer (3): Another nameplate would not be required if it does not affect capacity, stability, or safe operation.

Question (4): Is section 7.5.9 referring to removable attachments, does the fork truck require a nameplate if the attachment does not affect the capacity or the safe operation of the truck?

Answer (4): Removable attachments that do not affect capacity, stability, or safe operation do not require a nameplate.

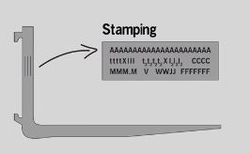

When inspecting forks be sure to review the legibility of the stamping located on the side of the fork. ISO 2330 and ANSI B56.1 require these to be legible or the forks should be taken out of service.

Important! When using the GenieGrips® Caps, licensed forklift drivers must enter the pallet at a 90-degree angle and allow sufficient clearance above and below tyne when entering/ exiting to ensure Cap installation is not compromised.

According to ANSI 56.1 section 6.2.8:

Inspection and Repair of Forks in Service on Fork Lift Trucks(a) Forks in use shall be inspected at intervals of not more than 12 months (for single shift operations) or whenever any defect or permanent deformation is detected.

If your forks don't measure up, check our Forks - Stock for replacements today.

Follow the link below to view safe operating video on Wright self dumping hoppers