When it comes to protecting your valuable products the forks handle, Fork Sox forklift fork covers are the ultimate solution. Unlike generic alternatives, all Fork Sox fork covers are custom made to order, ensuring a perfect fit for any size of forklift fork you have. This tailored approach not only guarantees optimal protection but also reduces the risk of damage to both your equipment and your goods.

It’s important to note that because each set is crafted specifically for your requirements, there are no returns on these products. This policy allows us to focus on delivering high-quality, bespoke solutions that meet your exact needs every time. Whether you need covers for unusually shaped forks or unique dimensions, Fork Sox can be made in any size—making them an ideal choice for businesses seeking reliable and customized protection. Choose Fork Sox forklift fork covers and invest in long-lasting durability designed just for you.

When it comes to upgrading your ride with Fork Sox, precision matters. That’s why our recommended tolerances—1/2" from top to bottom and 1/2" from left to right—are more than just numbers; they’re the key to an easy, hassle-free installation. These specific measurements ensure that your Fork Sox fit snugly without being overly tight or frustratingly loose. By sticking within these tolerances, you’ll find the ease of installing is unmatched—no stretching, no awkward adjustments, just a perfect fit every time. Whether you’re a seasoned mechanic or a weekend DIYer, following these guidelines means less time in the garage and more time enjoying your ride. Trust in the 1/2" top-to-bottom and left-to-right tolerances for seamless installation and optimal performance.

If you’re tired of dealing with the constant mess caused by splintered pallets, it’s time to consider the Pallet Dawg accessory—a forklift accessory that can reduce trash on the floor from splintered pallets. This innovative tool is specifically designed to address one of the most common headaches in any warehouse environment: broken pallet debris littering your workspace.

By attaching the Pallet Dawg to your forklift, you’ll dramatically cut down on cleanup time and improve overall safety. No more worrying about employees tripping over stray wood fragments or damaging equipment due to scattered pallet pieces. Not only does this accessory keep your floors cleaner, but it also helps extend the life of your pallets by ensuring they’re handled more gently.

Don’t let splintered pallets slow down your operations or compromise safety. Invest in a forklift accessory that can reduce trash on the floor and transform your warehouse into a cleaner, more efficient space—the Pallet Dawg is truly a game-changer for modern material handling.

When it comes to protecting your valuable product, Fork Sox fork covers stand out as the gold standard in product protection. Made from woven nylon, these covers offer superior strength that is unmatched in the industry. The durability of woven nylon ensures that your fork covers can withstand the rigors of daily use, providing a reliable shield against wear and tear.

Investing in Fork Sox means you are choosing a product designed to enhance the integrity of your product. Don't compromise on quality; choose Fork Sox fork covers for peace of mind and superior protection that truly makes a difference in your operations.

When it comes to pipe handling, the importance of protecting your materials cannot be overstated. This is where Fork Sox come into play, especially for coated steel pipes. These innovative protective sleeves are designed specifically to shield your valuable pipes from damage during transportation and handling.

The coating on steel pipes is crucial for preventing corrosion and ensuring longevity. However, when forklifts are used to move these pipes, the risk of scratches to the coating layer increases significantly. Fork Sox effectively mitigate this risk by providing a cushioned barrier between the forklift forks and the coated surface of the pipe. This means that you can transport your materials with confidence, knowing they are safeguarded against potential harm.

Investing in Fork Sox not only protects your coated steel pipes but also enhances operational efficiency by reducing the likelihood of costly repairs or replacements due to damaged coatings. In a competitive landscape where every detail matters, ensuring that your materials remain in pristine condition is essential for maintaining quality standards and customer satisfaction. Don’t compromise on protection—choose Fork Sox for reliable pipe handling today!

When choosing a color in a facility setting, it’s important to keep a few key factors in mind to ensure that the result meets your expectations and standards. Here are three critical things to consider:

Functionality and Visibility

• Purpose of the Color: Does the color need to stand out (e.g., for safety signs, machinery, or warnings) or blend in (e.g., for specific product aesthetics or branding)?

• Contrast and Readability: Make sure the color provides enough contrast for visibility, especially in environments with low light or color-coded systems.

• Environmental Factors: Consider how the color will interact with lighting conditions and dust/debris in the factory. For example, darker colors may show dirt more easily.

Durability and Maintenance

• Material and Finish: Different colors might be available in various finishes (e.g., matte, gloss, textured). Some finishes may be more resistant to wear and tear, which can be important in a factory environment where surfaces are subject to friction, chemicals, or temperature fluctuations.

• Ease of Cleaning: Some colors (especially lighter ones) may require more frequent cleaning to maintain their appearance, so make sure to choose one that suits the maintenance schedule and cleanliness requirements of the factory.

• UV and Chemical Resistance: If the factory is exposed to sunlight or harsh chemicals, choose colors and materials that are UV-stable or resistant to chemical exposure.

Brand Consistency and Employee Morale

• Branding Alignment: If the factory color is part of your brand identity (for machinery, uniforms, etc.), ensure that the color chosen aligns with company branding guidelines. Pucel can color match to provide you with the exact color to fit your brand.

• Psychological Impact: Color can influence employee mood and productivity. For example, blue can create a calm atmosphere, while red might promote alertness or urgency. Consider how the color might affect the workplace environment and employee morale.

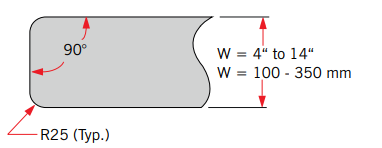

Above is the standard tip for replacement forks, other tips are available or the design center can make what you need.

When it comes to protecting your valuable assets, the size of your Pipe Defender Forklift Covers matters significantly. Available in both 8" wide and 12" wide models, these covers are designed to fit a variety of applications, ensuring that you get the best protection for your specific needs. They are only available in those 2 sizes. Refer to our Product highlights for the complete dimensions.

This a great illustration of why we pay attension to details. I'm sure we can match up a platform to your OrderPicker.

In today’s unpredictable economic landscape, understanding tariffs is more crucial than ever. Volatile world events can significantly impact trade relationships and, consequently, the tariffs imposed on various goods. These changes can affect pricing structures and availability of products in the market.

It’s essential to stay informed about these fluctuations, as they can have a direct effect on your purchasing decisions and business operations. Rest assured that if any adjustments to tariffs occur, you will be contacted promptly with updates. This proactive communication ensures that you are always aware of how external factors may influence your transactions and helps you navigate these complexities with confidence. Embracing this knowledge empowers you to make informed choices in an ever-changing economic environment.