Spark retardant forks are used on lift trucks operating in hazardous locations. These include places such as chemical plants, grain elevators, mines, paint plants, munitions, arsenal manufacturing, and storage facilities.

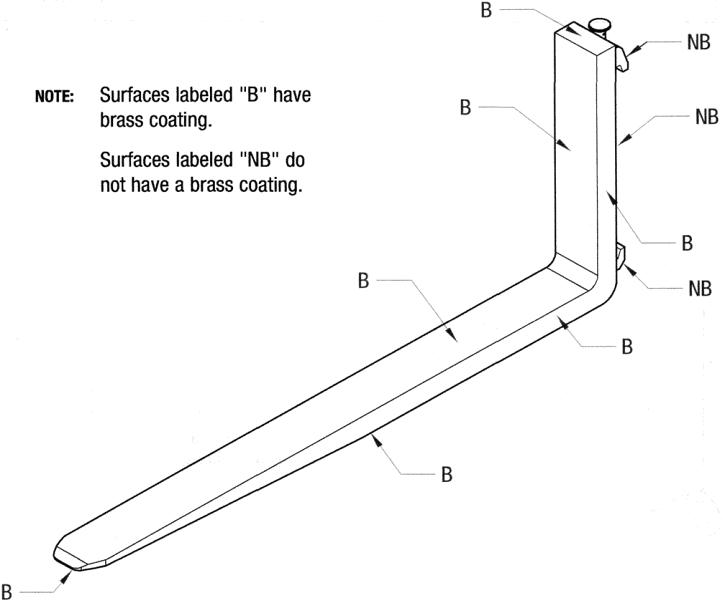

The most popular spark retardant fork is covered in ASTM B36 alloy 6 brass that is 0.125" thick, (except rear of upright and hooks) and brazed 100% along all seams.Similarly coated forks (using stainless steel) are also available for the food industry though these are not spark retardant.

The most popular spark retardant fork is covered in ASTM B36 alloy 6 brass that is 0.125" thick, (except rear of upright and hooks) and brazed 100% along all seams.Similarly coated forks (using stainless steel) are also available for the food industry though these are not spark retardant.